Five Engine Types: Piston, Turbine, Electrical, Hybrids, New

Summary of Engine Types

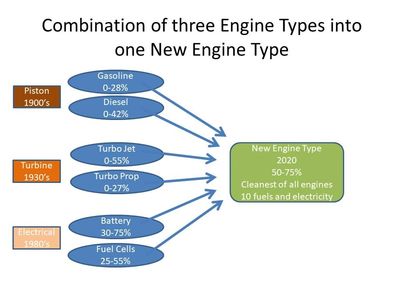

There were four engine types historically.

Now there are five engine types:

1) Piston- Otto or Diesel

2) Turbine- Jet or Turbo Prop

3) Electrical- Battery or Fuel Cell

4) Hybrids- Electric, Pneumatic, or Hydraulic

5) New Engine Type- A combination of all types in one

The New Engine Type tech combines the best parts of each of the other four types into one engine system and eliminates the negative characteristics of each. See "Comparison of New types" in link for a spreadsheet comparison. .https://newenginetype.com/comparison-of-engines

This New Engine Type tech should be 3-15 time less fuel/energy and CO2 emissions than other engine types depending on application and duty cycle. The engine tech can be easily recycled and does not involve heavy rare earth metals, other than stainless steel found in common exhaust systems in cars today.

This New Engine Type is as profound to aviation and transportation as the jet engine was when Frank Whittle invented the jet engine in the late 1920's.

What this is not... is another remake of old piston engines, jet engines, electrical or hybrid systems.

This New Engine Type tech has NOT BEEN DONE BEFORE anywhere and is original and very disruptive to energy and how it is used. It helps enable fuels made from nuclear or renewable energy electricity called Electro-fuels (NH3, N2H2, NH4-OH, C8, C10) by making fuel-use instead of battery-use the low cost and low energy means compared to other types of systems, especially Battery Electric Vehicles.

This in turn allows the replacement of oil and the revenue to do so from these pure electro fuels that can be used in fuel cells and this New Engine Type tech. The use of Electro-fuels can then lead to Electro-plastics and the 100% replacement of oil.

(Note, this is NOT the focus of this development at this time. First engines for airplanes and trucks, then solar for renewable energy, then fuel making for 100% RE - big picture.)

EVs rob revenue for Electro-plastics for the replacement of oil because they don't use fuels. Without a means to use waste fuels from oil (Gasoline, Diesel, Kerosene), plastics cannot come from oil. EVs then must fund electro-plastics without the aid of electro-fuels which are precursor to electro-plastics. First fuels, then plastics. EVs slow the progress to get off of oil, if wanted (not our goal).

This New Engine Type tech enables so many new types of vehicles and systems unable now with current types of IC engine systems or electric systems. It also enables Solar Thermal electricity generation which enables 100% independent solar from a house or building without the need of any grids.

This New Engine Type tech makes piston (Otto, Diesel) and turbo props, as well as electrical and hybrids OBSOLETE in reality.

It does NOT replace large airliner size turbine jet engines, but does make small aircraft MORE fuel efficient per passenger than large transports, thus making airlines indirectly obsolete.

This New Engine Type tech is designed for airplane applications from sea level to 25,000 feet, 0 to 400 mph, and 3 to 6000 HP. With the additional equipment, 50,000 feet could be achieved if wanted, but is not the focus of this development. Constant power to 14,000 feet is designed into airplane applications, with 25,000 feet enabled with additional considerations.

Pressurization is not the focus of this technology, but easily can be part of the system with a qualifying airframe. "Bleed" air similar to turbines is afforded to allow 50,000 feet cruise at Sea Level effective elevation without additional equipment, if wanted.

In short, the New Engine Type is the solution to energy.

Piston: Otto cycle engine (gasoline)

An Otto cycle engine, or gasoline engine, uses gasoline and is 5-10% efficient City, 15-20% highway, with an average of around 13.5% (according to GM). The peak efficiency, which occurs only during moderate accelerations (50-75% of torque) is around 25-30%, depending on engine systems. There are many variations, but they all are spark ignition and mix gasoline fuel prior to compression. They are limited in compression ratio to below 10-12 to 1 due to auto-ignition potential of the premixed fuel and therefore do not have the higher efficiencies of high compression engines like Diesels.

In airplanes, the size of the engine and need for many pistons (to smooth out the engine) forces two basic design configurations: engine in the front and back (tractor or pusher) or two engines laterally on the wing to the sides (twin). This packaging problem makes for dangerous airplane configurations (single or twin) as compared to having many small motors on the wing or on the center body.

The redundancy of having many motors is key to air safety. A single or twin configuration is not enough safety to allow low insurance costs and low cost of manufacture. When a motor can fail and nobody gets disrupted in the flight, or worse, injured or killed, the cost of everything goes down. This in turn lowers insurance costs which drive costs, especially in training applications.

Instead of 2 engines laterally for a twin, this New Engine Type engine system would have 4 to 8 engines laterally on the wings. When one fails on one side, the opposite engine it turned off. The remaining engines are balanced in thrust and two motors are off instead of just one. This gives partial power without the unbalanced thrust of a twin with one engine running. This is much safer than a single or twin by at least 100 x.

The package size of the Otto engine drives all IC engine vehicles designs, whereas the New Engine Type at 5 inches diameter and 10 inches long, can fit in most places, such as in wings or on struts out to the side and behind the prop cone. This design flexibility is NOT possible with a single Otto engine of any useful size.

The noise and emissions of an Otto engine is a major consideration, most of which is solved with this New Engine Type tech. There are many types of vehicles and applications that are NOT possible with an old Otto engine that are enabled with the New Engine Type tech.

Package size and weight are one of the most important factors of the New Engine Type tech. Even if the New Engine Type were the same efficiency as an Otto engine, it would be a huge improvement to the vehicle design. The only difference would be the old Otto engine fuel flows of about 2.4 times more (60% vs 25% is 2.4 ratio).

This point about packaging and flexibility cannot be understated, yet it is very much overlooked. It is key to new types of vehicles not able with old IC engines.

In short, the old Otto engine is:

1) not the right size or shape,

2) it uses more fuel/power by 2.4 to 15 times,

3) heavier by 2.5 times in airplane apps,

4) not made for distributed power,

5) not able to turn off and on quickly,

6) not good with drive shafts.

In fact, there are 100 ways to mess up an engine, and Otto engines mess up 85 ways and the new engine type messes up NONE. See https://newenginetype.com/comparison-of-engines

Piston: Diesel Cycle Engine (Diesel Fuel)

Diesel engines are used in trucks for their higher efficiency of up to 35-42% when worked hard under loads above 50% of torque. Small engine power in semi trucks with heavy loads, forces the engine to work at the peak efficiencies most of the time. This issue of working hard is valid for any engine as well as for Diesels and Otto engines, but Diesels have an advantage over Otto engine due to the cycle peak efficiency of 42% compared to 25-30% for Otto engines. The Diesel's higher compression ratio, turbocharger and the ability to add fuel on a variable basis as the piston moves down, allows the Diesel to have high torque.

Ironically, an Otto cycle is MORE efficient than a Diesel cycle at the SAME compression ratio. The fact that fuel is injected near Top Dead Center for a Diesel engine and not mixed prior to compression allows the Diesel to have higher compression ratios and thus higher efficiency than an Otto cycle.

This injection of fuel however forces the engine to run slow due to the time needed to burn the fuel. Premixed fuel (gasoline engines) will vaporize and allow quick combustion. Sprayed in fuel takes more time to burn, and Diesel fuel burns slower than gasoline fuel. This sprayed fuel can create hot zones of fuel droplets that cause emissions problems of NOx and HCs.

With the new engine type tech, igasoline or Diesel fuel can be used, as well as 8 other fuels, and it makes little to no difference in the efficiency on an energy basis. The engine can take most any type of fuel and will adapt to the needs of each easily.

Why then a Diesel engine? In short, efficiency of 42% vs 25-30% for Otto engines.

Compare a semi truck to a car.

A car is 4000 LB with 200 hp. 4000/200 = 20.

A Semi Truck is 80,000 LB with 500 hp. 80,000/500 = 160 160/20 = 8.

A semi truck would need 8 times more HP or 500 x 8= 4000 HP to accelerate like a car does. That would add around 22,000 lbs of engine and more for structure and make the fuel consumption go up by 2-3 times per mile at low power as a percent of total.

A semi struck needs around 250 HP to cruise at 65 mph at 80,000 LB and Cd = 0.6. Notice that 250 hp is around 50% of 500 hp. This keeps the engine working hard while cruising on a flat road. This requires many gears to allow the engine to run in the efficient range of 1200-1600 RPM for a Diesel. Such is not attractive for a car...

On the large size end of Diesels are the massive diesel engines found in ocean freighters that are up to 55% and run very slow (100 rpm) with turbo boosting and complex systems. They compress the air without a throttle and inject the fuel as the piston expands, thus coming close to a Brayton cycle similar to a jet engine (isobaric).

The biggest problems with Diesels are emissions and the need for exhaust treatment, as well as the heavy and poor package size. Power pulses require at least 8 pistons with a 4 stroke engine for propeller applications and this makes for a large engine. Burn speed of the fuel limits how fast the engine can run and thus how much power per weight it can make.

These problems are corrected in the new engine type tech and the emissions are ultra clean due to how the fuel is combusted and for how long. Engine speed for this New Engine Type is NOT limited by the burn speed for all fuels except NH3 where mechanical limits and burn speed approximately coincide.

Turbine: Turbo Jets

A Jet engine compresses air in stages, burns fuel at constant pressure and runs the gas out to drive a turbine fan that in turn runs the compressor. The air then flows over 2 or more turbine fans that drives the ducted fan (high bypass jet).

Jet engines are very light weight per power at up to 15 HP/LB, compared to a Diesel at 1/6th HP/LB, and an Otto engine at 0.5 HP/LB. The New Engine Type tech is at around 1.25 HP/LB system wise and 3 HP/LB for each motor on the wing.

Jets can only be made efficient in large sizes due to the smallest compressor blades and boundary layer effects. To obtain 25:1 compression ratios where it becomes 55% efficient at the core, as found on a Boeing 787 core, it takes a huge engine, and thus a very large airplane that need such a large engine.

Jets must be run with fast airplanes and cannot be turned on and off quickly. They have a time delay in power variation which requires much better pilot skills than private pilots. This delay in power makes them totally unsuited for door to door applications or the road, not to mention the hot gases, noise and large size vs power.

Jets are well suited for large airplanes, but not for small applications. Size requirements lead to huge engines at constant power (90-100% of torque) and high altitude at near 0.8 Mach. At low altitude and slow they quickly become inefficient, noisy and low thrust. Jets cannot slow down the airplane speed and get the huge fuel savings that the New Engine Type tech gets. Door to Door travel is not a valid option for jets.

They are best for high speed airplanes at high altitude or for supersonic speeds, such as with fighter jets. They are best for very long distances and quickly become noncompetitive at lower altitudes (25k or below) and slower speeds (below 400 mph).

Turbine: Turbo Props

Turbo props engines are a jet engine with a gear set that runs a propeller at slow RPM instead of a bypass fan with a duct. The engine is much smaller than jets engines and therefore limited in the size and thus efficiencies. Older turbo props were around 8-9 to 1 compression ratios and an efficiency of around 21%. Newer engines are 12 to 1 compression and are around 27%. This is par to old piston aircraft piston engines at 25-30% found in small airplanes. The power is usually in the range of 500-6000 hp.

The size issue for the smallest compressor blade is the limiting factor for efficiency. The efficiencies increase as the size increases due to the physical issues of boundary layer and blade size. This makes them unable to get efficient power from 1 hp to 6000 hp in one engine, like the New Engine Type tech can. A single 6000 HP engine might be 45% efficient at 6000 HP, but that same 6000 HP engine at 10% of power (600 HP) might be around 5% or 9 times less efficient per power.

The turbine is connected to a gear box that sets the speed of the prop in a narrow range due to compressor considerations. Unless some type of gear shifting were enabled, the prop cannot be slowed without a drop in efficiency in the engine occurring. This prevents ultra quiet cruise with props at 1/2 peak speeds due to the need to keep the compressor at a narrow speed range. This inability to vary power by speed (RPM) with a Turboprop is a big disadvantage in future AI drones and taxi applications that will dominate the future of air travel, thus making this tech obsolete in applications where props need quick power and speed variation.

To run on a road and in the air, the engine must be able to turn on and off quickly, like an electric motor, as well as change power levels quickly and dramatically from full to none. Braking recovery is also a huge plus in city driving, which a turbo cannot do. In short, just like a jet, a turboprop is NOT suited for any road applications.

Thus, turboprop technology will become obsolete due to the advantages of the new engine type tech in the prop market segment or niche. With the addition of the 3-10 times lower fuel flow for a given power at slower speeds and Active Drag Reduction with the New Engine Type tech, it is hard to see why turbo props would be needed. The weight of a New Engine Type system will be similar to the weight for a Turboprop. The New Engine Type can replace Turboprops in the same cowling by running many motors to one common shaft to get the power needed at the point of application (prop).

This fact of obsolescence of Turboprops is in contrast to jets that have a market segment (large, high and fast airplanes) or niche not affected by the new engine type tech. The use of a prop limits Turboprops to below 400 mph just like it does with the New Engine Type system.

The New Engine Type tech will not be going into large airliners due to the high efficiencies of current jets (55%) and the lack of future markets for large jet with the advent of door to door air travel, making most airline travel OBSOLETE.

Why be searched by the TSA when you can go door to door in a private airplane for less cost and time? Why have masks and other nonsense due to health risks, real or imagined? Private travel is the future, NOT public.

Yes, airliners will go the way of trains... When small is MORE efficient in fuel and time, the reason for big is gone... Add in AI and the advantage is with small private transit, NOT airlines.

Electric: Battery and Fuel Cell (Electricity as Fuel)

An electric system has electric motors that are supplied entirely by a battery or fuel cell DC electric source. It is not an engine hybrid with a combustion engine as the motive power for a generator as a source of electricity for the motors.

With the advent of new high speed electronics and power electronics in the early 1990's, electric cars became much more efficient and thus viable to those people interested or focused on renewable energy.

The idea of Renewable energy is to generate electricity from wind and solar and charge the battery and not use combustion of fuels. CO2 is the claimed reason for this investment, as well as air pollution from poor engine combustion.

Historically, electric motors were heavy, low power and inefficient. With the advent of power electronic modules, the size of which can exceed the size of the motor, electric motors became very efficient (up to 90-95%), when worked correctly with these extremely complex controllers. They can however be as low as 30% or less at low power in city driving.

This is in contrast to IC engines at 5-10% in city driving, making electrics 3-6 times more efficient in city and on average around 4-5x better than Otto engine cars or light trucks. The New Engine Type is about equal in efficiency to an electric system, and 1.5 to 2x better city with low power due in part to no battery weight and distributed power (many motors).

The power modules are extremely complex and full of millions of connections. The system is very costly and requires massive production volumes to lower costs with massive automation. The material issue alone is a major issue in supply, requiring rare earth metals and toxic mining, as well as materials that are toxic to dispose of or recycle.

The major problems with battery and fuel cell electric systems, outside the toxic materials, are the battery weight, charge time and safety. Fuel cells save some weight in the battery but still require a battery of some size to take surge loads due to the inability of the fuel cell to vary power quickly.

Batteries also have life cycle and charging issues, and degrade over time. These three issues doom it to be obsolete as a drive means once the New Engine Type system is developed and ready for market.

The battery as a concept is fundamentally flawed due to the fact that both the anode and cathode elements are stored in the same container. A battery is in effect a torch or flair when shorted. This risk is not acceptable in aviation nor should it be in cars, trucks or buildings. The inability of firemen to extinguish the fire is a show stopper for those who are interested in real safety. This same "show stopper" is found in hydraulics with micro leaks that can inject oil into skin causing amputation.

In an aircraft, the battery would have to be ejected to prevent the airplane from burning up in flight, requiring difficult design constraints. Few airplane or drone designers using batteries deal with this reality. Certification will be very costly and frankly near impossible without risky exemptions by the FAA. The New Engine Type tech does not have these key critical flaws.

EVs with Battery-only or fuel-cells-with-battery makes a car around twice as heavy, or more, as the New Engine Type system using fuel instead, in the same body shape. The extra weight leads to around 25% less economy at highway speeds and 2x in the city for EVs.

Add in active drag reduction technology with the New Engine Type system, and the highway economy could be 2x better than an EV as well as in City. This active drag reduction can cut airplane drag by up to 50% without resorting to extreme laminar shapes, and even more with laminar shapes.

The slow charging rate of a battery makes an EV a costly choice in terms of time to fill. A pump can fill 10 gallons per minute in the USA. It takes only 2 minutes to fill 20 gallons of fuel, but 1.36 hours to fill an 85 kwh battery to 80% of charge at 50 kw. 80% of 85kwh is 68 kwh. 68kwh/50kw = 1.36 hrs. At 33.7 kwh/gallon gasoline equivalent (GGE), 68 kwh equals 2 gallon of gasoline in energy (68/33.7=2.01).

It takes 80 minutes to charge 2 GGE in Battery energy vs 2 minutes for 20 gallons of gasoline, or ten times the energy. 80/2=40 minutes/GGE. Pumping gasoline is 0.1 minute/Gallon. Ratio is 40/0.1=400:1

It takes 400 times LONGER to charge a battery than to pump fuel per unit of energy at 50 kw.

With the New Engine Type at the same efficiency as an Electric system, and 1.5 times the economy in a car, the ratio of time to charge per distance is 400 x 1.5 = 600 times longer per distance. At 200 kw charging rate an EV would take 150 times longer per distance.

TRUCKS

In trucks, the requirement for 500 miles (8 hrs of driving), and the weight of the battery to go 500 miles, limits the load an EV Truck can carry as compared to a truck with a New Engine Type system.

To drive 500 miles at 65 mph and 14.52 mpg for a Tesla would require a 1160 kwh battery. At 80% it would be 1450 kwh. The battery alone would weigh 17,912 lbs at the same weight found in Tesla Model 3 at 12.35 lbs/kwh (1050lbs/85 kwh= 12.35 1450 x 12.35 = 17,912). Assume 18,000 when installed as dead cargo weight. The New Engine Type system would be ~ 18,000 lbs lighter for the tractor at 500 miles range.

As a comparison, a Diesel is ~19,000 lbs. The New Engine Type in new truck would be around 10,000 lbs for the tractor and the Tesla tractor would be ~ 28,000 lb. With an old Diesel truck load common at 45,000 lbs, the New Engine Type would be at around a 54,000 lb load and the EV at would be around 36,000 lbs, with all three trucks at 80,000 lb gross. The cargo weight advantage of the New Engine Type is 54/36=1.5 x over an EV with the SAME aerodynamics and gross weight.

The battery makes freight more costly in an EV per cargo weight by 1.5 x when at 80,000 lbs limit than a semi with the new engine type. Hauling around a 18,000 lbs of battery is not a smart thing to do when it is not needed with the new engine type. Notice the battery weight is around 1/2 the max cargo weight (18k vs 36k cargo). Houston, we have a big fat heavy battery problem...

The fuel economy is affected by 18,000 lbs lower weight. For example, a Tesla truck at 80k lbs would get 14.52 mpge. The New Engine Type in a Tesla truck would be 18,000 lbs lighter and get 17.26 mpg with the same trailer. 17.26/14.52=1.18 At 10,000 lbs cargo or 54,000 lbs gross, the Tesla would get 18.83 mpge. The New Engine Type would be 36,000 lbs and get 23.7 mpg. 23.7/18.83 =1.26. When empty, the Tesla would be 44,000 gross and 21.26 mpge and New Engine Type would be 26,000 gross at empty and 27.68 mpg. 27.68/21.26=1.3. The battery is the problem...

Summary of weights: The new engine type in a new truck would have a tractor weight of around 10k lbs. An old Diesel is around 19k lbs, depending on cab. An EV tractor would be around 28k lbs or around 2.8x heavier or 18,000 lbs heavier.

With fuel at current prices of $2.0/gal Diesel with no road tax and electricity and battery at $3.68/GGE battery and 12 cents/kwh retail electricity ($4/GGE), the cost of an EV truck will be 7.68/2.0=3.84 x more than with New Engine Type. The discounted cost of electricity for Tesla at 5.23 cents/kwh promoted to sell trucks would be $1.76/GGE. 1.76+3.68=$5.44/GGE with battery. 5.44/2=2.72 x more with subsidized electricity. At 28 cents/kwh (likely future rate) it is $9.44/GGE + 3.68 battery = $13.12/GGE. 13.12/2=6.56 x more for EV truck.

That ratio of energy cost then is multiplied by the cargo ratio of 1.5 when weight is critical and 1.18-1.3 for loads where weight is not key. Best to worst ratio is: 2.72 x 1.18 = 3.2 to 6.65 x 1.5=10. 3.2 to 10 x. Likely is at 12 cents/kwh (3.84x) and 1.18 to 1.5...4.53 to 5.76 x more for a Tesla.

If only energy marginally is considered without any battery costs considered, then the ratio is 1.76/2 x 1.18 =1.03 to 9.44/2 x 1.5=7.08... 1.03 to 7.08 times more. At no time will a Tesla be less costs even if the battery were free.

Summary of costs: Average is around 5 times MORE costs for a Tesla EV truck over the same shell of the truck (same aerodynamics) with the New Engine Type. In the cut throat world of trucking it is GAME OVER for Tesla or ANY EV truck maker...

That said, Tesla will likely only have a 300-500 kwh battery making it close to a day cab at 16,000 LBs and a sleeper at 19,000 LBs, thus allowing it to haul the same loads as a Diesel. This requires the driver to spend 5 hrs charging for 10 hours of driving. That makes for a duty cycle of 15 hrs with only 10 hrs of driving, all which is NOT paid for on a per mile basis. The driver is the loser and must donate 5 hrs/day to time charging the stupid battery without pay, cutting pay by 33%.

CARS

With the electric vehicle 2x weight for a given car, the road tax should be twice as much as car that has the New Engine Type system in it. A 4000 lb car (Tesla Model 3, for example) vs 2000 lb car with the same power and New Engine Type, would be typical for a 4 place car. If road tax is 2 cents/mile for the 4000 lbs EV, the new engine type car would be 1 cent/mile.

At $2/gal fuel and 200 mpg ($2/200 mpg= 1 cent/mile), the road tax AND fuel for the 2000 lbs car equals the road tax for an EV without fuel or battery costs. As the tax rate goes up on the basis of weight x distance, as it should, a point is reached that an EV would not compete even if electricity AND battery were FREE simply due to road tax difference due to weight. If fuel costs $2/gal for a 200 mpg car and road tax 1 cent/mile, that point is reached.

What will kill the EV? ROAD TAX. Fuel + road tax on fuel car at 1/2 weight = road tax on EV. It is like driving for free fuel compared to an EV.

Electricity is very expensive and in some countries it is now $30.33/gal equivalent to gasoline (90 cents/kwh) to charge an EV. The battery is up to 12 cent/kwh ($4/gal) to use it and this is added to the 30.33 for a total of $34.33. Gasoline is now over $2.0/gal for the fuel (no tax), which is less than 1/2 the cost of electricity in the USA (12 cent/kwh). When the electricity and battery costs $4/GGE each, fuel then is 1/4th the cost of electricity and battery ($8/GGE).

Clearly, the buyer of an EV should be aware of the true costs of an EV. EVs are a classic bait and switch scam. Tesla started with free charging and now super charging is 28 cent/kwh ($9.44/gal), and that does not include the battery costs ($4/gal) and road tax ($2.6/gal) at 2 cents/mile for a 4000 lbs car at 130 mpge...

$16/GGE is about the right cost for an EV.

Do the math:

$9.4/GGE super charge,

$4.0/GGE battery,

$2.6/GGE road tax (2 cents/mile @ 130 mpge = $2.6)

Total = $16/GGE.

A fuel car with New Engine Type would be:

$2/gal,

$2/gal road tax (1 cent/mile x 200 mpg)at 1/2 weight,

Total = $4/gal.

16/4=4x.

In the city driving the economy would be twice or 2x. 4x2=8x less cost.

Then factor in 1.25 x for heating/cooling in cold/hot city driving and you end up with city driving cost ratio of 10x MORE for EV than for New Engine Type.

10x more Costs for EV over New Engine Type in cold city driving!

Same for CO2:

2x for CO2 to make battery over driving with gasoline,

2x better economy.

2x for Grid at 550 g CO2/kwh vs 264 for gasoline

1.2x for heating from battery.

Do the math: 2 x 2 x 2 x 1.2 = 10 x more CO2!

RANGE

The range would be 4000-10,000 miles for a 20-50 gallon fuel tank, compared to 260 miles for a battery at 2 GGE 80% charge (85kwhx0.8/33.7=2).

If the same car were to have a fuel tank of 190 gallons, the AVERAGE weight would be 4000 lbs, which would equal the Tesla Model 3 weight. The average economy would be the same as the EV initially due to the fuel weight, at 130 mpge.

Range would be 130 mpg x 191.546 gallons =24,901 miles, which is ~ 1 times around earth on one 19 minute fill up at 10 gallons/minute, plus credit card use for 20 minutes. A Tesla does 1 GGE in 40 minutes at 50 kw. 20 minutes is 1/2 GGE. At 130 mpge with 1/2 GGE you can drive 65 miles. 24700/65=380:1 Notice how carrying all that fuel (weight) drops the ratio from 600:1 to 380:1, as calculated above. Lower weight = better economy!

Summary: The new engine type makes an EV obsolete due to the 10x factors of cost, CO2 and range... Any product that is 10 x less fuel/energy or better makes the competition obsolete.

The features enabled by this New Engine Type system, not discussed here, will make an EV look even less attractive from a big picture perspective with respect to housing and solar fuel making....

This is shared in hope someone will listen. EVs are NOT the answer to anything.

This New Engine Type is the solution to our energy problems.

Electro Fuels from Thorium nuclear and New Engine Type use of fuels are the future, NOT toxic EVs. Please read this section over and over until you understand these concepts!

Hybrids: Electrical, Pneumatic and Hydraulic

A hybirds have three main types of outputs:

1) electrical

2) pneumatic (air)

3) hydraulic

Each has three main parts:

1) prime mover (torque)

2) generator, pump, compressor

3) Output motors that use the supplied energy transfer means.

which are electric motors, pneumatic motors, hydraulic motors

The main advantage of a hybrid is the output can be removed from the prime mover input, which is usually large and bulky. A small electric motor can be put on a wing and the prime mover and generator can be put in the tail cone, for example, thus eliminating a lot of drag with the entire engine system being on the wing.

Similar to electric system, pneumatic hybrid can be done with pneumatic motors when compressed air is sent to a pneumatic motor for use in a small light weight motor. Dentists use pneumatic motor to hold in their hand while drilling. Metal worker use air grinders to run pneumatic grinders wheels with low inertia.

Hydraulics are used throughout heavy industry, farming and industry. Hydaulic motors can be very low weight and high power compared to pneumatics and electrics. The main advantage is the non compressible nature of the fluid allows instant off and on power switching without the "spring" residuals of pneumatics.

Storage

Each hybrid type can have storage added to it to allow motor/output use when the prime mover is not functioning for short duration power.

Electrical hybrids have batteries as storage.

Pneumatic hybrids have pressure tanks as storage.

Hydraulic hybrids have accumulator tanks as storage

With the addition of storage, many interesting effects can be added to a system over which a prime mover (engine) cannot do by it self. The use of storage is NOT a new concept and is as old as the original engines and motors.

New Engine Type is NOT a "hybrid" system per se, as the prime mover is not separate from the system of energy conversion as it is in hybrids where the fuel is converted in a single system that then drives a generator/compressor/pump.

New Engine Type: A combination of all types in one

This new engine type is new and unique to engines. It has never been done before. It is not a spin-off from old concepts like 99.9% of the other "new" engines are. It is all new. It is NOT an electric motor system, but it can run on electricity, such as from a battery. It is different from any other engine type and has most of the benefits of electric motor systems, as well as the benefits of combustion engines, both piston and turbine.

It is was originally invented for grid electricity generation, and as such has many motors that work together, just like the grid does, that work to a common purpose. It can work together with many motors in many ways to add or subtract (brake recovery) power as needed in a distributed fashion, both separately with multiple props on wings or wheels, or together as a group to one common shaft. Motors can be combined to a common shaft to vary the power by turning off motors as needed to maintain efficiency, or by allowing task switching as needed, such as with track hoes (hydraulic equipment with many implements).

The engine system has a compressor group, somewhat like a jet engine does, with compressor and turbine, that supplies air to the motors, that then provides torque, similar to how a Jet engine works. It is modeled after a jet engine, ironically, but eliminates the negatives factors of a turbine, allowing the best of pistons and jet engines to come together in ONE system.

It can run on over 10 different fuels, one of which is NH3 (the "new" hydrogen), which is difficult to burn, due to the slow burn rate. Billions of dollars has been spent on NH3 combustion, yet nobody has a solution that will work using old Piston or Jet engines. This new engine type is the only know engine that could potentially use NH3 well.

The engine can also use electricity as a heat source and operate at zero CO2 emissions when needed, for garages and confined spaces, depending on battery supply, or where crazy outlaw governments have banned combustion, even though this technology is 3-10x less CO2 than an EV. Drive slowly on battery and then switch to fuel for flight from road. A small battery would do the job.

The engine can use solar thermal (hot water) to run the engine, which in turn turns an electric generator, similar to how the grid works. It can thus make electricity from solar that then can be used to power electrical loads as needed, or make fuel (NH3 or other fuels) to be stored for later use in house applications.

This engine enables and makes valid the energy path from electricity to fuels instead of electricity to battery, as most renewable energy proponents propose.

This is a key "disruptive" point that changes the entire Renewable Energy equation.

This New Engine Type allows the SAME efficiency of the power system compared to an Electrical Vehicle, yet it can get up to 2-3 times better economy due to lower weight, active drag reduction and new types of vehicles not yet proposed. 520 mpg Highway economy is very doable with this technology in a low weight 800 lbs three place tandem vehicle.

This ability to use "active drag reduction," which can cut aerodynamic drag by up to 50%, becomes especially important in air vehicles that work with air. This feature, not found with electric power systems, allows this engine an efficiency par (equal, give or take) to Electrical systems, yet it can be up to twice as efficient as a flying system (power plus air frame) due to active drag reduction and power on lift technology enabled by the unique properties of this New Engine Type.

The engine can allow distributed props found on "quads" that use electric motors, thus making electric motor systems inferior for large passenger VTOL drone applications. It also makes quad type craft obsolete by allowing safer craft that are not prone to single point failure like quad craft are.

The new engine type has a high efficiency (60-75%) that will be par to electric vehicles, thus eliminating any efficiency advantages Electric system may have over a combustion engines.

This new engine type can lead to 8x better fuel economy in old cars. With entirely new car designs, specific to the unique abilities of this engine, it could have an economy of 200 mpg highway and 300+ city. This is due to lower weight by 1/2 that of an electrical system, active drag reduction and high efficiencies at low power (1-3 KW) where city driving (25 mph) occurs often.

The engine also enables advanced crash protection 4 times better than airbags. This is perhaps the most important enabling aspect of this technology. In order to get cars that are below 2000 lbs, new crash protection 4x better than airbags is needed or the occupants will be killed due to large weight differences between the low weight cars and existing cars and trucks. The engine enables this protection.

The engine can have expansion ratios of up to 81 to 1, not just 8-12 for Otto (gasoline), 16-22 for Diesels and 8-25 for jets/turbines. This engine allows the full expansion of air, as well as a cycle that can be varied as needed, including combined cycle (somewhat like GE's combined cycle grid machines, but better and micro). All old IC engines are a single cycle device.

This new engine type has the design flexibility that will allow it to achieve (potentially) world record efficiencies (above 60%) and to MAINTAIN them from high to low power, unlike all other motor systems, including electrical.

The use of many motors lowers the need for many gears, allowing the use of only three gears: high, low and reverse. It does not need 4-6 gears normal to cars, and 10-18 for semi trucks.

In airplane applications, the props can be direct drive or multiple motors can be ganged up via a common gear to drive one prop at a reduced speed, as needed, thus allowing a wide range of power settings while maintaining high efficiency over 60%. By turning motors on or off as power demand varies, a nearly constant 60% efficiency is maintained, whereas with other engine systems, the fuel consumption goes up per power as the power level drops.

This ability to remain efficiency at low power is key to fast and slow air transit. Fly fast (300 mph) or slow (150 mph) and get around 3.5-4 x better fuel economy at slow (150 mph). A turbo prop, for example, will double fuel consumption per power at 1/3 power. At 1/8th power, where you get 1/2 speed (150 mph vs 300 mph), a turbo can be 2.5-3x more fuel per power, thus eliminating most of the 4x gain from slower speeds. Piston engines also suffer this problem, but to a lessor extent, and is the reason most airplanes fly with full power most of the time.

This feature of constant efficiency over a wide range of power allows high power for VTOL or Super STOL takeoff, yet the power can be greatly reduced for slow cruising in city flying and touring, or when cargo loads are low and noise or fuel economy is key. This allows a cargo airplane to slow down to best L/D where the best fuel economy is when the cargo bay is empty on a return flight, thus saving lots of fuel. With AI drone tech, where no human pilot exists, time is a variable that can save fuel by flying slow.

The ability to drop the RPM of the prop from max (tip speed 80% of sound, 880 ft/sec) to 1/2 max allows the prop to run slow and quiet. Turbines cannot "shift" gears and must maintain near constant speed to maintain compression ratios and efficiencies.

This quiet mode ability is key to any city or taxi service, and without it, the craft will be limited by noise considerations. Electric motors can do this, but old piston and turbines cannot without much higher fuel consumption per power.

Clearly, this New Engine Type is superior to anything now on the market.